|

|

|||

|

|

1-digit BCD adder with LCD (design phase #2) |

|

|

|

|

|||

1-digit BCD adder with LCD display

(Under revision)

1. Specifications

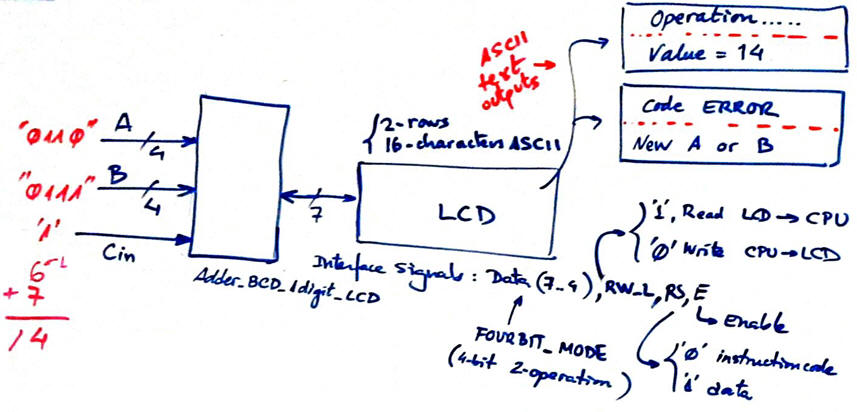

Implement the second design phase of the application Adder_BCD_1digit. The idea is to enhance the circuit replacing the 7-segment displays by an LCD display to show operands and results.

Entity name: Adder_BCD_1digit_LCD. Use the PIC18F4520 microcontroller chip.

|

Fig 1. Symbol of the device to be designed. |

2. Planning

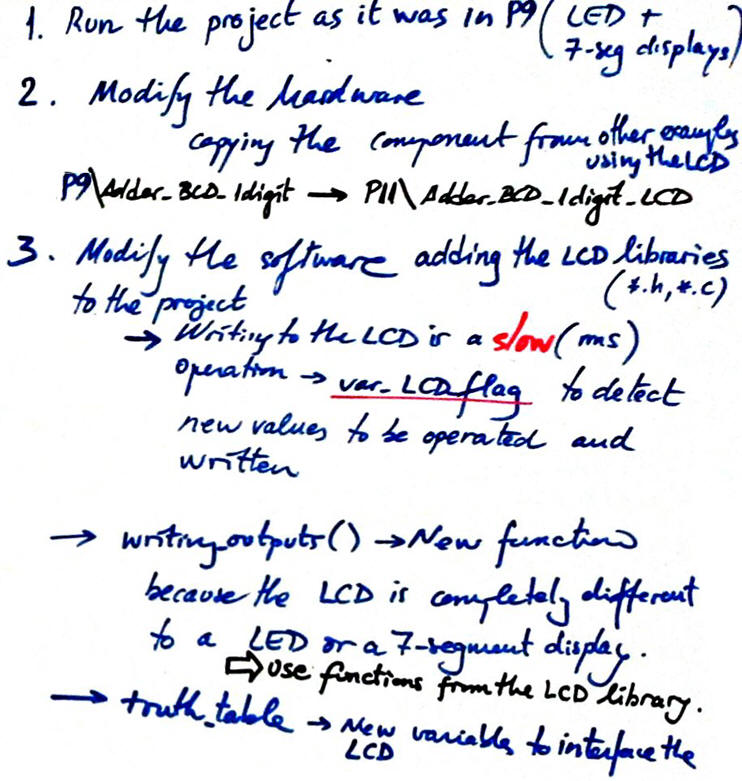

Ideas and discussion.

|

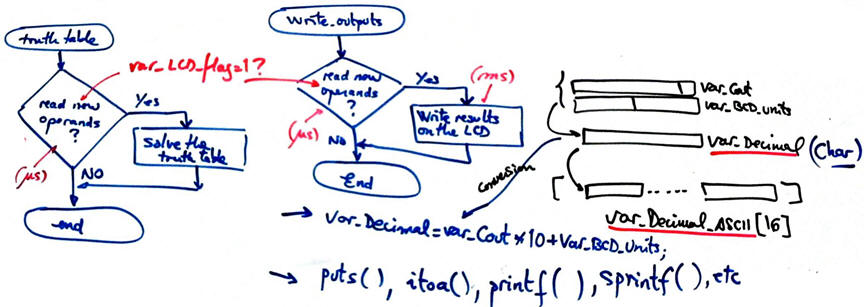

Fig. 2. Planning ideas. |

A) Planning hardware

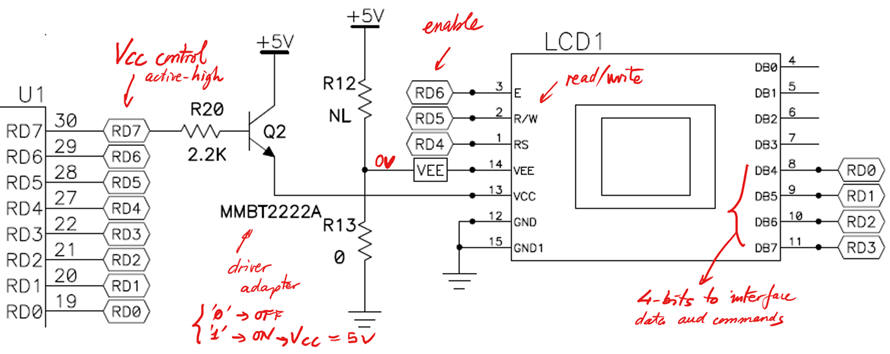

A good idea is to connect inputs and outputs in free pins of PICDEM2 Plus prototyping board. In such board LCD display is connected to microcontroller's PORTD.

|

|

Fig. 3. Connecting 7 wires for the LCD interface and another one (RD7) for switching ON/OFF its power supply. |

A) Planning software

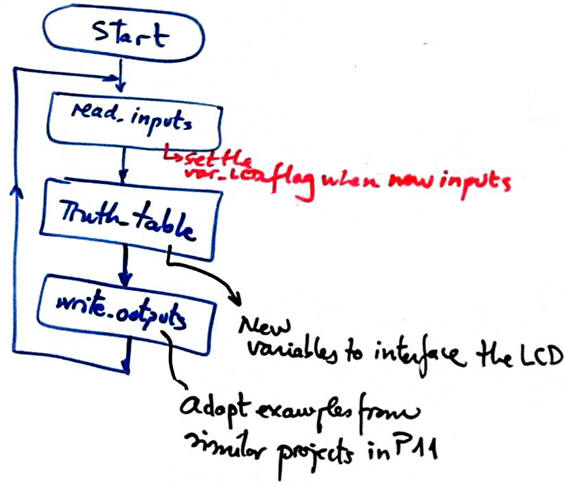

Software modifications indicated in the main loop.

|

Fig. 4. Software modifications. |

Represent the RAM variables required in this application. What is var_LCD_flag? Why we need such indicator?

|

Fig. 5. New RAM variables. |

|

|

Fig. 6. Hardware-software diagram. |

Explain the new ideas in init_system(). Where the LCD is configured?

Explain how the flowchart of read_inputs() is modified.

Explain how the flowchart of write_outputs() is modified.

|

|

Fig. 7. Activate var_LCD_flag when new operands are polled. |

Organise a MPLABX - XC8 IDE project targetting a PIC18F4520 at location:

C:/CSD/P11/Adder_BCD_1digit_LCD/(files)

3. Development - 4. Testing interactively

A) Developing hardware

Proteus hardware circuit Adder_BCD_1digit_LCD.pdsprj.

|

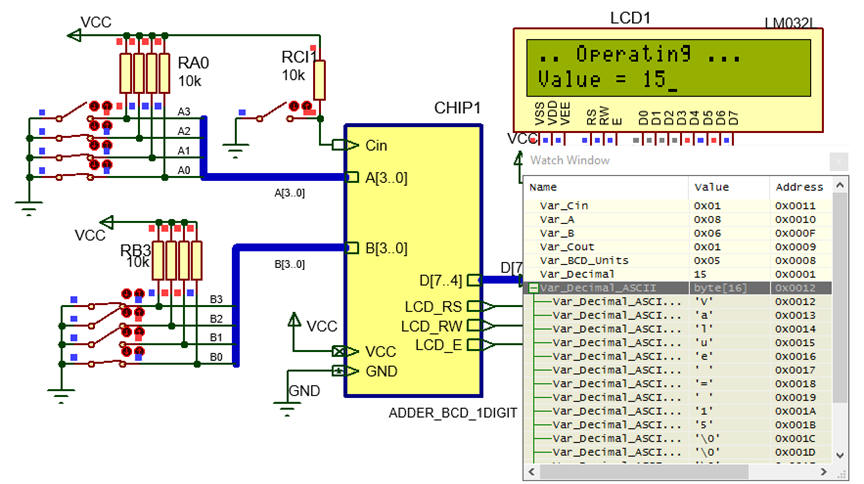

Fig. 8. Circuit captured in Proteus. |

B) Developing software

C source code Adder_BCD_1digit_LCD.c.

|

Fig. 9. Using LCD functions for writing ASCII messages. |

C) Step-by-step testing

Run the Proteus simulator. Do it in step by step mode while watching variables and placing break points, specially for following var_LCD_flag.

|

Fig. 10. The circuit in "run" mode while monitoring the variables in the "watch" window. |

|

NOTE: This is yet another version of the same project where dynamic data is ajusted to 2 bytes (plus the end of string code '\0' null terminator). It shows how to represent dynamic numerical data, in this case an int result (Var_Decimal) from an arithmetic operation to a char string (Var_Decimal_ASCII[16] or Var_Decimal_ASCII[3]) sized for LCD. Similar formatting (sprintf()) is required for representing double int or float variable types. |

5. Report

6. Prototyping

Use training boards such PICDEM2 or EXPLORER 8.